Replace injection molding with cost-effective 3D Rapid Printing

What is unique about 3D printing at Prattville?

What is unique about 3D printing at Prattville?

Anyone can print a 3D part. Where Prattville leads is we can precision machine your rapid print 3D models for tolerances within .001 inches (.025 mm).

A cost-effective tool when considering injection molding.

Using Carbon technology, we can make a part faster, with more detail, at a lower price point than with traditional injection molding. And our 3D Carbon printing technology is not just for prototyping. We can offer you full production.

|

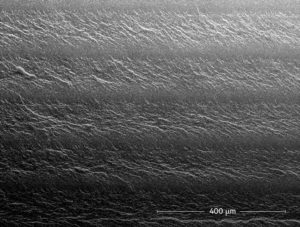

TRADITIONAL 3D printed parts are notoriously inconsistent. Their mechanical properties vary depending on the direction the parts were printed due to the layer-by-layer approach.

|

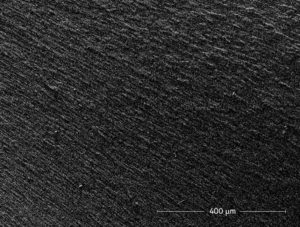

DIGITAL LIGHT SYNTHESIS™ Parts printed with Digital Light Synthesis™ are much more like injection-molded parts. Digital Light Synthesis™ produces consistent and predictable mechanical properties, creating parts that are solid on the inside. |

CONTACT US TO LEARN MORE

3D Printing at Prattville using Carbon’s CLIP™ Technology

Carbon works at the intersection of hardware, software, and molecular science. Their vision is a future fabricated with light, where traceable, final-quality parts are produced at scale with CLIP technology. CLIP — Continuous Liquid Interface Production — makes this vision possible by combining engineering-grade materials with exceptional resolution and surface finish.

HARNESSING LIGHT AND OXYGEN TO PRODUCE OBJECTS FROM A POOL OF RESIN, CLIP is a photochemical process that eliminates the shortcomings of conventional 3D printing by harnessing light and oxygen to rapidly produce objects from a pool of resin. From everyday products like tennis shoes and electronics, to industrial components, to highly customizable medical devices, CLIP makes it possible for creators to design the parts and products of the future.

The Process

Despite industry advances, traditional approaches to additive manufacturing force trade offs between surface finish and mechanical properties. In contrast, Digital Light Synthesis™ technology, enabled by Carbon’s proprietary CLIP™ process, is a breakthrough technology that uses digital light projection, oxygen permeable optics, and programmable liquid resins to produce parts with excellent mechanical properties, resolution, and surface finish.

Materials

Featuring the widest range of properties in additive manufacturing, our materials uniquely

combine high resolution, exceptional surface quality, and mechanical properties tuned for

production. From consumer product elastomers to high-temperature automotive materials, our offering is growing at an unprecedented rate.

TAILORED MATERIALS

Your challenges are specific. Our materials can be just as precise.

Carbon’s Dual Cure technology gives Prattville unmatched flexibility to customize materials for some of the world’s most exciting design challenges.